|

|

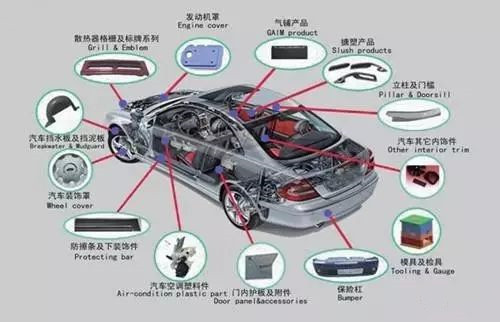

Application of injection molding technology in the field of automotive plastic partsDue to the distinctive particularity of plastic parts of complex automobile parts, the following factors need to be fully considered in the design of injection molding, such as drying treatment of materials, new requirements of glass fiber reinforced materials for screws, driving form and clamping structure. Firstly, when the commonly used resin materials such as automobile bumper and instrument panel are modified resins such as modified PP and modified ABS, the resin materials have different hygroscopicity. In order to meet the water content requirements during molding (General requirements ≤ 0.2%), the resin raw materials must be subject to hot air drying or dehumidification drying before entering the screw pre molding measurement of the injection molding machine. The moisture absorption of modified PP (ppepdm) resin is small. Generally, hot air dryer can be used for 2-3H at 80-100 ℃. Modified ABS (pcabs) has strong moisture absorption. Before molding and drying, dehumidification dryer shall be used for dehumidification and drying. We have fully considered the function application of dehumidification and drying system in the design of automobile complex plastic parts forming system. Second, at present, domestic automotive plastic parts are basically non glass fiber reinforced plastic products. Compared with the use of short cut glass fiber reinforced resin, the material and structure of the screw of the injection molding machine used to form non glass fiber reinforced plastic parts are quite different. When designing the injection molding machine, we should pay attention to the alloy material and special heat treatment processing technology of the screw barrel to ensure its corrosion resistance and strength. Third, due to the difference between auto parts and conventional products, its cavity surface is very complex, with unequal stress and uneven stress distribution. In the design, we should focus on the processing capacity it needs. The processing capacity of injection molding machine is reflected in two aspects: clamping force and injection molding capacity (expressed by the maximum theoretical injection volume). When the injection molding machine is molding products, the clamping force must be greater than the opening force generated by the mold cavity pressure, otherwise the parting surface of the mold will be separated and overflow will occur. The formula for determining the clamping force of the injection molding machine is as follows: P clamping ≥ P cavity × F/100。 Where: P is the clamping force (or clamping force) kN of the injection molding machine; The P-shaped cavity is the average pressure of the mold cavity, MPa, which is related to the product structure shape, accuracy requirements and the number of cavities per model, and the value range is generally between 25-40mpa; F is the horizontal overlapping projected area cm3 of mold cavity, sprue and feed inlet. In order to ensure reliable mold locking, the process mold locking force during injection molding must be less than the rated mold locking force of the injection molding machine. The maximum theoretical injection volume of the injection molding machine matches the clamping force tonnage of the injection molding machine, which is the nominal injection volume of the injection molding machine with polystyrene (PS) as the benchmark resin before leaving the factory. Fourth, according to the characteristics of complex plastic parts of the automobile, the driving form of the injection molding machine and the design of the clamping mechanism are mostly used in China. At present, the hydraulic elbow of the hydraulic mechanical type or the full hydraulic type, or the injection molding machine of the central direct pressing clamping mechanism. After years of efforts, Tairui Machinery Co., Ltd. has broken through the traditional constraints and developed a mechanical structure in the form of two plate die clamping, direct pressing and composite die locking. The advantage of this structure is that its mold opening stroke is much larger than the hydraulic elbow mold closing structure, at least more than twice, which can meet the production demand of large plastic parts of automobile. The compound die locking structure with large tonnage can be used to lock the die. Secondly, the locking force of the hydraulic elbow is higher than that of the hydraulic die, and the locking force is higher than that of the hydraulic die. The precision of forming composite surface of large and complex plastic parts of automobile is fully guaranteed. Fifthly, because the cavity surface of auto parts is very complex, the particularity of the injection molding machine should be considered in the design, and some special function programs should be configured: such as multi group core pulling function, timing control function, supporting mold changing device function of the injection molding machine, supporting part taking manipulator device function, etc. These special functions have obvious advantages in the production of automotive plastic parts. Auto plastic parts accessories injection molding processing factory

|